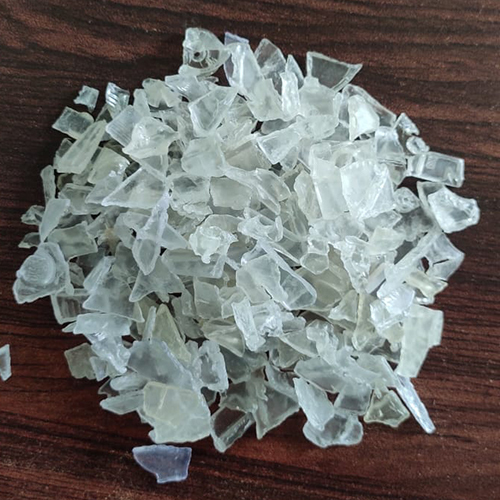

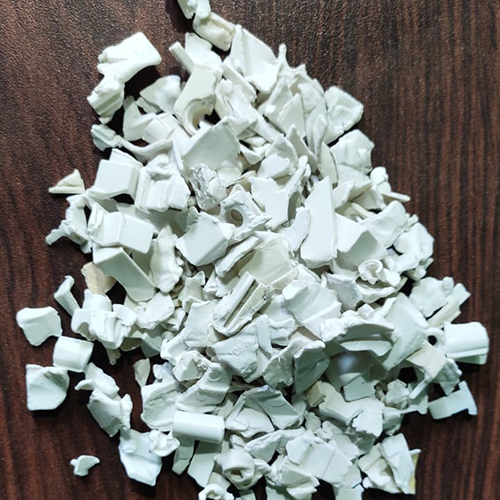

Efficient and Durable Cavity Connectors, PC Scrap, PP Scrap, and

Rubber Pads

Established in 2022, Prince Trading Company is a growing manufacturer

and trader committed to delivering high-quality industrial components

and materials. We specialize in the production and supply of Cavity

Connectors, as well as trading premium-grade PC Scrap, PP Scrap, and

Rubber Pads. Our products are widely used across various manufacturing

and recycling industries due to their reliability, durability, and

cost-effectiveness. Backed by a customer-focused approach and efficient

supply chain, we strive to meet diverse client requirements with timely

delivery, consistent quality, and competitive pricing.

Our Manufacturing Unit & Machinery

At Prince Trading Company, our manufacturing unit is the backbone of our operations, enabling us to produce high-quality components with precision and efficiency. Located in a well-connected industrial area, our facility is equipped with modern machines and tools that support both small and bulk production requirements.

We use advanced machinery such as:

Quality Control

At Prince Trading Company, quality is at the core of everything we do. We follow a strict quality control process to ensure that every product leaving our facility meets the highest industry standards for performance, durability, and consistency.

Our dedicated quality assurance team conducts thorough inspections at each stage of productionfrom raw material sourcing to final packaging. We use precision measuring tools and testing methods to verify specifications, strength, and overall integrity of products like Cavity Connectors, PC Scrap, PP Scrap, and Rubber Pads.

Key quality practices include:

Our Manufacturing Unit & Machinery

At Prince Trading Company, our manufacturing unit is the backbone of our operations, enabling us to produce high-quality components with precision and efficiency. Located in a well-connected industrial area, our facility is equipped with modern machines and tools that support both small and bulk production requirements.

We use advanced machinery such as:

- Injection Molding Machines For manufacturing precision Cavity Connectors and rubber components

- Plastic Scrap Grinders For processing PC and PP Scrap efficiently

- Hydraulic Presses For molding and shaping rubber pads

- Cutting and Finishing Tools To ensure clean edges and durable finishes on all products

Quality Control

At Prince Trading Company, quality is at the core of everything we do. We follow a strict quality control process to ensure that every product leaving our facility meets the highest industry standards for performance, durability, and consistency.

Our dedicated quality assurance team conducts thorough inspections at each stage of productionfrom raw material sourcing to final packaging. We use precision measuring tools and testing methods to verify specifications, strength, and overall integrity of products like Cavity Connectors, PC Scrap, PP Scrap, and Rubber Pads.

Key quality practices include:

- Material Testing Ensuring raw materials are sourced from certified and reliable suppliers

- In-Process Inspections Monitoring dimensions and tolerances during production

- Post-Production Testing Checking for strength, finish, and defects

- Customer Feedback Loop Integrating client input to improve product quality